Technology at Falcon Industries

At Falcon Industries, our state-of-the-art facilities in Abu Dhabi are equipped with a comprehensive suite of advanced technologies, enabling us to deliver superior plastic and fiberglass solutions with precision and efficiency.

Mono Extrusion

Our Mono Extrusion capabilities provide precise and consistent production of single-layer plastic films and profiles, ensuring high-quality materials for diverse applications.

Injection Moulding

Utilizing advanced Injection Moulding, we produce complex, high-volume plastic components with exceptional accuracy and intricate designs, perfect for demanding industrial and consumer needs.

Multi-Layered Extrusion

This sophisticated process allows us to engineer materials with customized barrier properties and enhanced functionalities, combining multiple layers to meet specific performance requirements for advanced packaging and industrial uses.

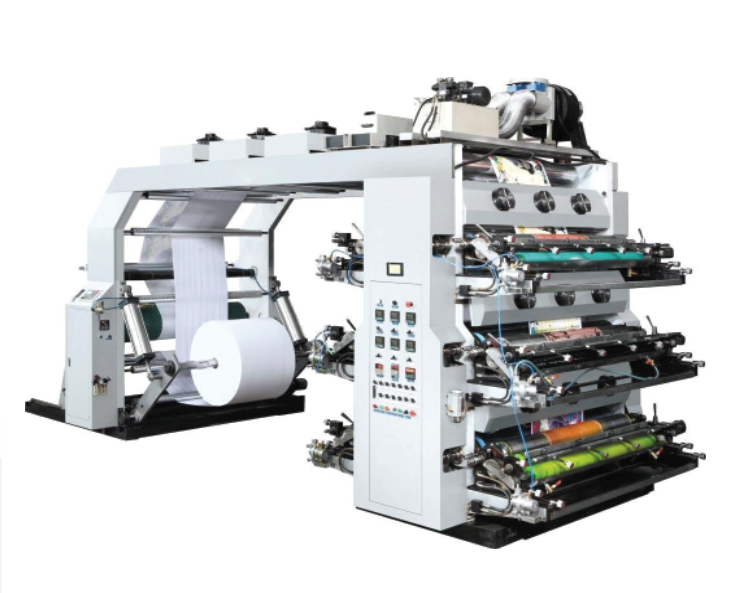

Flexo Printing

Our high-definition Flexo Printing delivers vibrant, crisp graphics and branding directly onto flexible packaging materials, ensuring your products stand out with premium visual appeal.

Recycling

Committed to a circular economy, our integrated Recycling processes transform plastic waste into valuable raw materials, underpinning our dedication to environmental sustainability and responsible manufacturing in the UAE.

Cold Sealing

Employing Cold Sealing technology, we provide efficient and secure packaging solutions ideal for heat-sensitive products, ensuring product integrity without thermal stress.

Slitting

Our precision Slitting capabilities allow for the accurate customization of material widths, providing tailored solutions to meet exact client specifications and optimize material use.

Lamination

Through Lamination, we combine different material layers to enhance strength, barrier properties, and overall durability, creating robust solutions for demanding applications.

Hand Sculpting

For bespoke fiberglass and decorative applications, Hand Sculpting showcases our artisanal craftsmanship, allowing for the creation of unique, intricate, and custom-designed pieces.

IMW Methods (In-Mould-Working/Welding/Labelling)

These integrated methods enhance product aesthetics and functionality by applying labels or joining components directly within the moulding process, resulting in seamless, high-quality finishes.

Hand & Spray Layup

Fundamental to our fiberglass production, Hand & Spray Layup methods provide versatility for creating a wide range of FRP products, from tanks to architectural features, with reliable structural integrity.

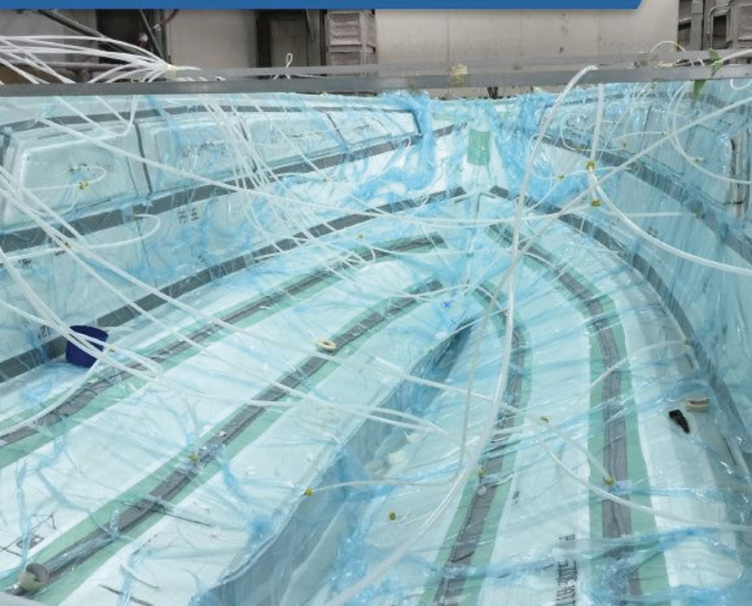

Vacuum Infusion

An advanced composite manufacturing technique, Vacuum Infusion ensures superior strength-to-weight ratios and minimal void content in our fiberglass products, ideal for high-performance and critical applications.

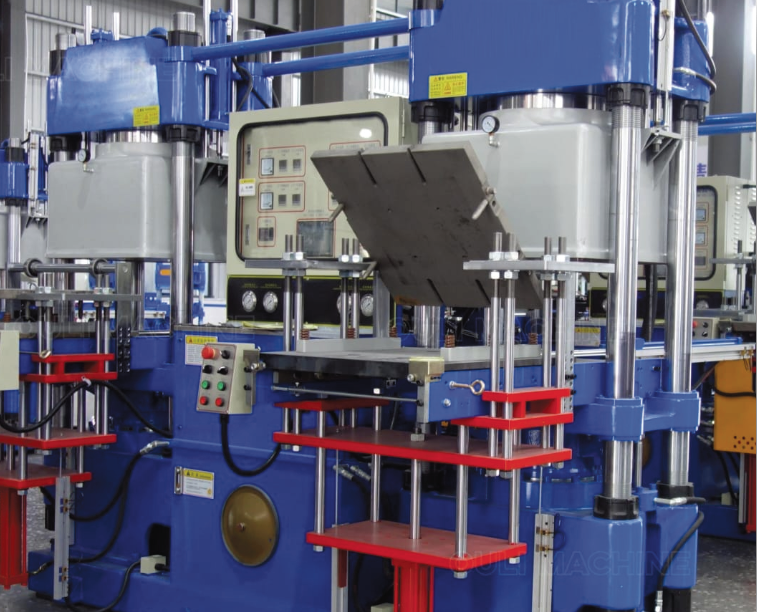

Compression Moulding

Our Compression Moulding capabilities allow us to produce high-strength, dimensionally stable composite parts with excellent surface finishes, suitable for challenging industrial and automotive sectors.